What is melamine cyanurate?

2025-06-19

Melamine cyanurate is a non-salt complex formed from a 1:1 molar ratio of melamine and cyanuric acid. It is distinct from a true salt because the two components are not ionically bonded but rather held together by an extensive network of strong hydrogen bonds. This unique bonding gives it specific properties that are highly advantageous for its primary application. Its chemical formula can be represented as C₆H₉N₉O₃, or more specifically, as C₃H₆N₆·C₃H₃N₃O₃, explicitly showing its constituent molecules.

What is Melamine Cyanurate?

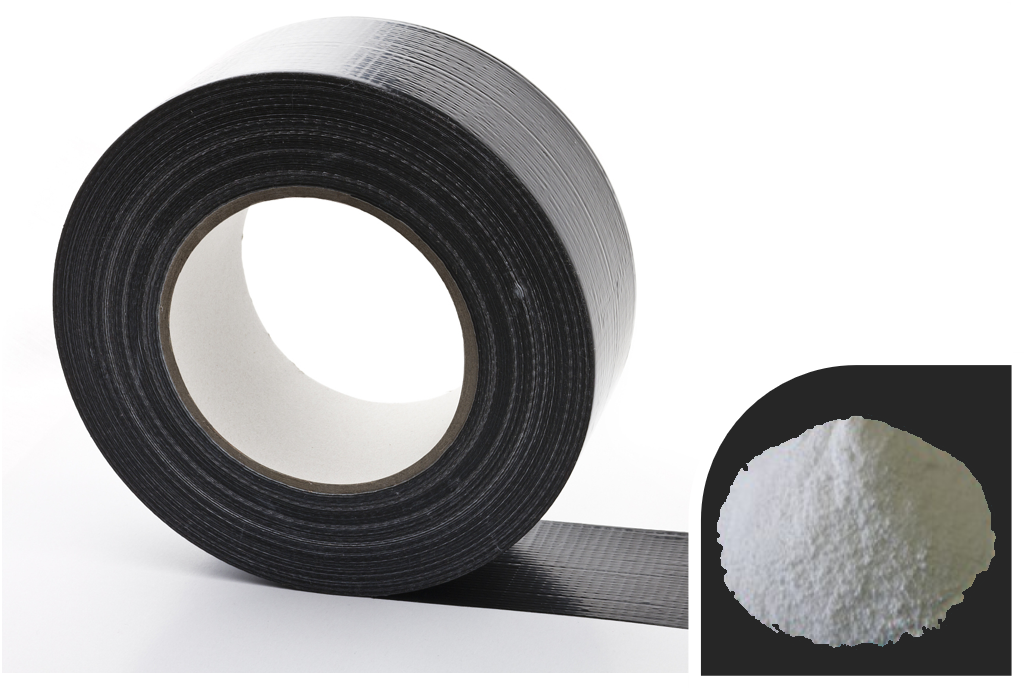

Melamine cyanurate (MCA) is a hydrogen-bonded supramolecular complex of melamine and cyanuric acid. It is a white, crystalline powder known for its high thermal stability and effectiveness as a halogen-free flame retardant.

Key Properties

Chemical Structure and Bonding:

Unlike ionic salts, MCA is formed through a complex network of hydrogen bonds between the amino groups of melamine and the hydroxyl/keto groups of cyanuric acid. This strong intermolecular bonding is responsible for its stability and crystal structure.

The 1:1 stoichiometry is crucial for the formation of this stable complex.

Thermal Stability:

MCA exhibits excellent thermal stability, typically remaining stable up to around 320°C to 350°C. This high decomposition temperature makes it suitable for use in polymers that require high processing temperatures, such as polyamides.

Above this temperature, it undergoes endothermic decomposition, which is a key part of its flame retardant mechanism.

Flame Retardancy Mechanism:

MCA functions primarily as a gas-phase flame retardant with some condensed-phase effects.

Endothermic Decomposition: When heated to its decomposition temperature (above 320-330°C), MCA absorbs a significant amount of heat from the fire. This "cooling effect" helps to lower the temperature of the burning material.

Release of Non-Combustible Gases: Upon decomposition, MCA releases non-flammable gases, primarily ammonia (NH₃) and nitrogen (N₂), along with carbon dioxide (CO₂) and water vapor. These gases dilute the concentration of combustible gases and oxygen in the flame zone, effectively suffocating the fire.

Char Formation: In some polymer systems, MCA can also promote the formation of a carbonaceous char layer on the surface of the burning material. This char acts as a barrier, insulating the underlying polymer from heat and oxygen, and inhibiting the release of further flammable volatile products.

Environmental and Safety Aspects:

Halogen-Free: One of its most significant advantages is that it is entirely halogen-free. This addresses growing environmental and health concerns associated with traditional halogenated flame retardants, which can release toxic and corrosive gases (like dioxins and furans) during combustion and are persistent organic pollutants.

Low Smoke and Toxicity: During combustion, MCA typically produces lower smoke density and less toxic fumes compared to many halogenated alternatives, improving fire safety and reducing harm to occupants and firefighters.

Low Volatility: Its low volatility means it is unlikely to leach out of the polymer over time.

Solubility:

MCA has very low solubility in most common organic solvents and water. This insolubility is beneficial for its performance in polymers, as it prevents leaching and ensures its long-term effectiveness. It is slightly soluble in acidic DMSO and aqueous acids.

Primary Uses and Applications

Melamine cyanurate is widely utilized as a halogen-free flame retardant (HFFR) in various materials, primarily in the plastics and polymer industries, to meet stringent fire safety standards (e.g., UL94 V-0 ratings). Its key applications include:

Polyamides (Nylons): This is one of its most important applications. MCA is exceptionally effective in unfilled polyamide 6 (PA6) and polyamide 6,6 (PA66), allowing these engineering plastics to achieve high flame retardancy levels for applications like electrical connectors, circuit breakers, and automotive parts.

Thermoplastic Polyurethanes (TPUs): Used in wire and cable insulation, hoses, and other flexible components.

Polybutylene Terephthalate (PBT): In electrical and electronic components.

Epoxy Resins: For printed circuit boards (PCBs), encapsulants, and coatings.

Adhesives and Sealants: Enhancing the fire resistance of bonding agents.

Coatings and Paints: Providing fire-protective properties to surfaces.

Textiles: For flame-retardant finishes in fabrics used in upholstery, curtains, and workwear.

Elastomers and Rubbers: In various rubber products requiring improved fire safety.

Polymer Foams: Such as rigid polyurethane foams, polystyrene foams, and polyethylene foams used in insulation and packaging.

Electrical and Electronic Components: In parts where fire safety is critical, given the risk of short circuits and overheating.

In summary, melamine cyanurate is a crucial halogen-free flame retardant that offers a desirable combination of high thermal stability, effective flame suppression through a unique decomposition mechanism, and an environmentally favorable profile, making it a preferred choice for enhancing fire safety across numerous industries.