Future development plans for composite flame retardants for PA materials

Future development plans for composite flame retardants for PA (polyamide) materials could include several strategic focuses:

Enhanced Performance: Continuously improving the flame retardancy performance of composite formulations to meet or exceed stringent fire safety standards, while also enhancing other material properties such as mechanical strength, thermal stability, and electrical properties.

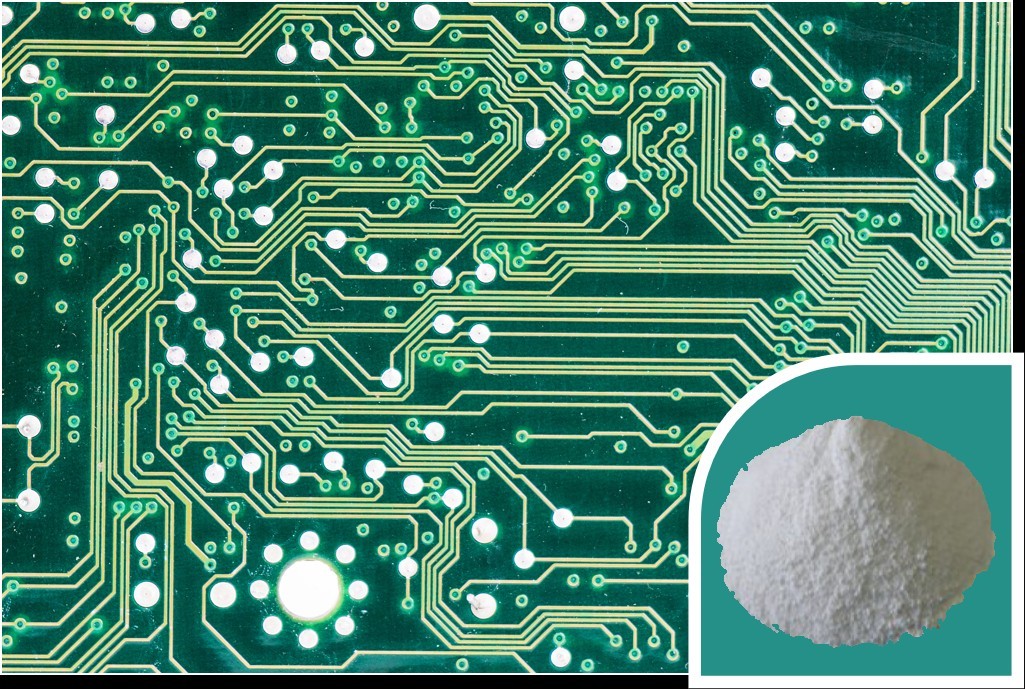

Environmental Sustainability: Increasing the use of environmentally friendly ingredients and processes in the production of composite flame retardants, aligning closely with global environmental directives and regulations (such as REACH, RoHS, and WEEE) to reduce environmental impact.

Application Diversification: Expanding the range of applications for PA materials in various industries such as automotive, electronics, construction, and consumer goods, by developing tailored flame retardant solutions that address specific industry needs and regulatory requirements.

Advanced Formulations: Researching and developing novel composite flame retardant systems that combine different types of flame retardant mechanisms (e.g., synergistic combinations of phosphorus, nitrogen, and silicon-based compounds) to achieve superior fire safety performance and material compatibility.

Collaborative Research: Strengthening collaborations with academic institutions, research centers, and industry partners to foster innovation in flame retardant technology, leveraging shared expertise and resources to advance product development and testing capabilities.

Market Expansion: Expanding production capacity and distribution networks to meet growing market demand for flame-retardant PA materials, both domestically and internationally, ensuring reliable supply chain logistics and customer support.

Regulatory Compliance: Proactively adapting to evolving regulatory landscapes by staying ahead of new regulations and standards, ensuring that all products meet or exceed compliance requirements in target markets worldwide.

By focusing on these strategic areas, Xusen can continue to lead in the development of composite flame retardants for PA materials, offering high-performance, environmentally friendly solutions that meet the diverse needs of global industries while ensuring safety and sustainability.

Composite flame retardant for PA always meets the key performance indicators or standards

Composite flame retardants for PA (polyamide) materials typically aim to meet several key performance metrics and standards to ensure effective fire safety and material integrity. Some of the common metrics and standards include:

Flame Retardancy Ratings: Products are evaluated based on their ability to inhibit or suppress the spread of flames when exposed to heat or fire. Standards such as UL 94, DIN 4102, or specific automotive industry standards like FMVSS 302 are often referenced.

Heat Release Rate (HRR): This metric measures the amount of heat released from a material when exposed to fire. Lower HRR values indicate better fire performance.

Smoke Density: The amount of smoke emitted during combustion is an important factor for safety and visibility. Standards like ASTM E662 or ISO 5659-2 specify limits for smoke density in materials.

Toxic Gas Emissions: The toxicity of gases released during combustion is critical, especially in confined spaces or in applications where human exposure is a concern. Standards like ASTM E1354 or ISO 19700 set limits for toxic gas emissions.

Mechanical Properties: Fire retardants should not significantly compromise the mechanical properties of PA materials, such as tensile strength, elongation at break, and impact resistance.

Environmental Regulations: Compliance with environmental directives such as REACH (Regulation (EC) No 1907/2006), RoHS (Restriction of Hazardous Substances Directive), and WEEE (Waste Electrical and Electronic Equipment Directive) ensures that products are safe for human health and the environment.

Long-Term Stability: The ability of flame retardants to maintain their effectiveness over the lifespan of the PA material, including under various environmental conditions (e.g., temperature, humidity, UV exposure).

Processing Compatibility: Compatibility with PA processing methods such as injection molding, extrusion, or compounding, ensuring ease of incorporation and uniform distribution within the material.

These metrics and standards ensure that composite flame retardants for PA materials provide robust fire protection while maintaining material performance and safety. Manufacturers like Xusen typically validate their products against these standards through rigorous testing and certification processes to ensure reliability and regulatory compliance.

+86-0573-89103923 / +86 182 6841 1181

+86-0573-89103923 / +86 182 6841 1181