Key considerations when developing flame retardants to meet the specific needs of each material type

Developing flame retardants that meet the specific needs of different material types involves several key considerations to ensure efficacy, safety, and regulatory compliance. Here are the key aspects that Xusen or any developer would typically consider:(Flame retardants for other uses)

Material Compatibility:

Chemical Interaction: Understanding how the flame retardant interacts with the base material (e.g., PA, PP, PBT, modified plastics) is crucial. Compatibility affects not only the effectiveness of flame retardancy but also the mechanical, thermal, and processing properties of the material.

Physical Form: Considering the physical form of the flame retardant (powder, liquid, masterbatch) and its ease of integration into the material during processing.

Flame Retardant Mechanism:

Mode of Action: Choosing the appropriate flame retardant mechanism (e.g., char formation, gas phase inhibition, radical scavenging) based on the combustion behavior and thermal stability of the material.

Synergistic Effects: Exploring synergistic effects between different flame retardant components (inorganic fillers, phosphorus compounds, nitrogen-based additives) to enhance overall fire performance.

Performance Requirements:

Fire Safety Standards: Meeting specific fire safety standards and regulations applicable to the end-use application (e.g., automotive, electronics, building materials).

Performance Criteria: Addressing performance criteria such as flame spread, smoke emission, heat release rate, and toxicity levels according to industry and regulatory requirements.

Environmental and Health Considerations:

Halogen-Free Formulations: Developing halogen-free flame retardants to mitigate environmental and health concerns associated with halogenated compounds.

Eco-Friendly Solutions: Incorporating bio-based or renewable materials to enhance sustainability and reduce environmental impact.

Processing Conditions:

Compatibility with Processing Methods: Ensuring that the flame retardant does not adversely affect the processing conditions (e.g., extrusion, injection molding) or the mechanical properties of the material.

Uniform Dispersion: Achieving uniform dispersion of the flame retardant throughout the material matrix to maintain consistent fire performance.

Durability and Longevity:

Heat and Aging Resistance: Evaluating the durability of the flame retardant under prolonged exposure to heat, UV radiation, and mechanical stress typical of the material's intended use.

Long-term Stability: Ensuring that the flame retardant maintains its effectiveness over the lifespan of the product, including during recycling or disposal.

Cost and Efficiency:

Cost-Effectiveness: Balancing the cost of the flame retardant formulation with its performance benefits and regulatory compliance requirements.

Efficiency in Use: Optimizing the dosage and application method to achieve the desired fire safety results without unnecessary material or production costs.

By carefully addressing these considerations, developers like Xusen can tailor flame retardant solutions to meet the specific needs of each material type while ensuring safety, compliance, and sustainability across diverse industrial applications.

Expected future trends of flame retardants in different industries

Anticipating future trends in flame retardants involves understanding evolving industry needs, regulatory changes, technological advancements, and sustainability considerations. Here are some expected future trends across different industries:(Flame retardants for other uses)

Textiles and Apparel:

Enhanced Sustainability: Growing demand for eco-friendly flame retardants that minimize environmental impact without compromising performance.

Integration of Smart Textiles: Development of flame retardant coatings or treatments for smart textiles with embedded sensors and electronics.

Customization for Fashion: Tailored solutions that meet fire safety regulations while maintaining aesthetic and comfort properties in fashion and home textiles.

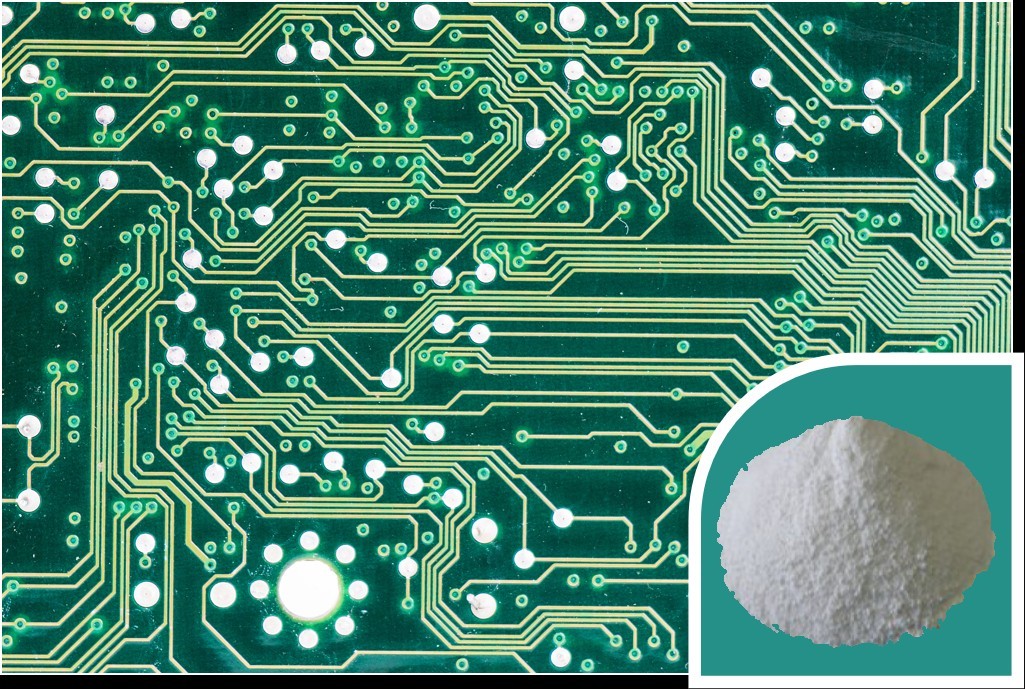

Electronics and Electrical:

Miniaturization and Heat Dissipation: Developing flame retardants that support heat management in smaller, densely packed electronic components.

High Reliability: Enhancing flame retardant formulations to improve reliability and durability in electronic circuits, batteries, and connectors.

Halogen-Free Solutions: Continued shift towards halogen-free flame retardants due to regulatory pressures and environmental concerns.

Construction and Building Materials:

Green Building Initiatives: Increasing demand for sustainable flame retardants that meet LEED and other green building certifications.

Fire-resistant Coatings: Development of flame retardant coatings for structural elements, insulation materials, and facades to enhance fire safety in buildings.

Integration with Smart Building Technologies: Incorporating flame retardants in smart building materials that monitor and respond to fire hazards.

Furniture and Upholstery:

Non-Toxic Solutions: Rising consumer preference for non-toxic and low-emission flame retardants in furniture and upholstery.

Recyclability: Focus on recyclable flame retardants that support circular economy principles in furniture manufacturing.

Performance in Real-World Conditions: Testing and validating flame retardant effectiveness under realistic fire scenarios to ensure safety in residential and commercial settings.

Aerospace and Defense:

High-Performance Materials: Development of flame retardant solutions for lightweight composites used in aircraft interiors and military applications.

Regulatory Compliance: Meeting stringent aviation safety regulations (e.g., FAR 25.853) with advanced flame retardant technologies.

Resistance to Harsh Environments: Ensuring flame retardants withstand extreme temperatures, humidity, and mechanical stressors typical of aerospace environments.

Healthcare and Medical Devices:

Biocompatible Materials: Research into flame retardants that are safe for use in medical devices and equipment, meeting biocompatibility standards.

Sterilization Compatibility: Developing flame retardants that maintain performance after repeated sterilization processes.

Emergency Response Preparedness: Enhancing fire safety in healthcare facilities with flame retardant materials that support rapid evacuation and fire suppression efforts.

Emerging Technologies:

Nanotechnology: Exploring the potential of nanomaterials for improving the efficiency and effectiveness of flame retardants in various applications.

Artificial Intelligence (AI) in Fire Safety: Integrating AI-driven systems to monitor and respond to fire risks, potentially enhancing the effectiveness of flame retardant materials.

Circular Economy Initiatives: Innovating flame retardants that are compatible with recycling processes, reducing waste and environmental impact over the product lifecycle.

These trends highlight the ongoing evolution in flame retardant technologies, driven by advancements in materials science, regulatory landscapes, and societal demands for safer and more sustainable products across diverse industries.

+86-0573-89103923 / +86 182 6841 1181

+86-0573-89103923 / +86 182 6841 1181