Flame Retardant Masterbatch: Enhancing Polymer Safety for a Safer World

2025-06-23

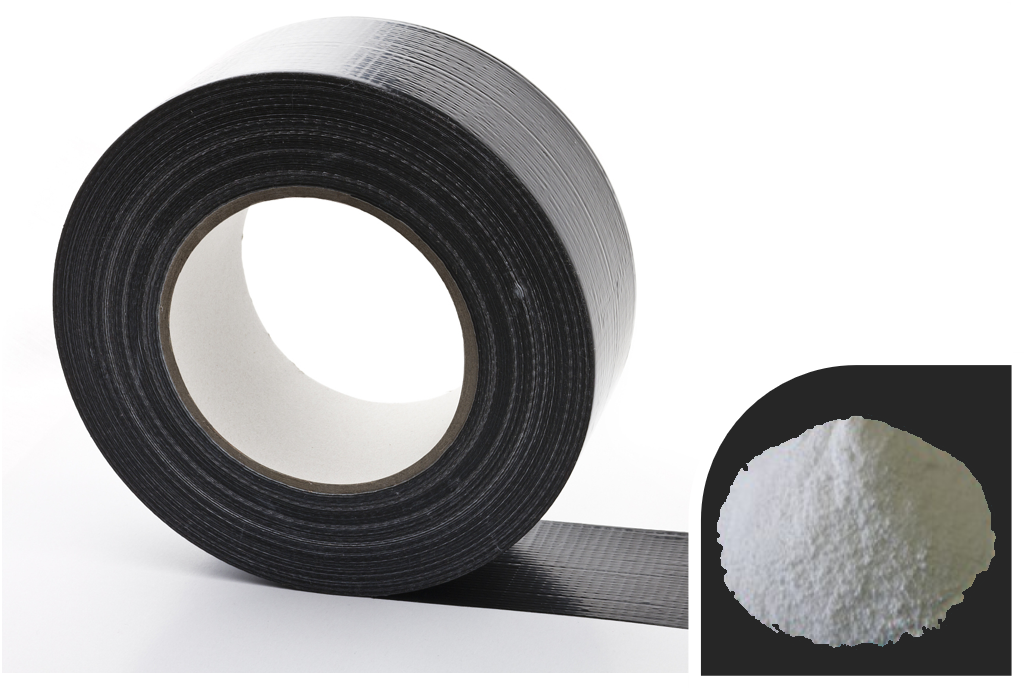

The pervasive use of polymers across countless industries – from construction and electronics to automotive and textiles – has revolutionized modern life. However, the inherent flammability of many polymeric materials poses a significant safety concern. This is where Flame Retardant Masterbatch plays a critical role, offering an efficient and effective solution to enhance the fire safety of plastic products.

What is Flame Retardant Masterbatch?

A flame retardant masterbatch is a concentrated mixture of flame retardant additives encapsulated within a polymer carrier resin. Instead of directly adding powdered flame retardants, which can lead to handling issues, poor dispersion, and health hazards, masterbatches provide a convenient, dust-free, and highly dispersible form for incorporating these crucial additives into virgin polymers during processing.

The carrier resin is typically compatible with the final polymer being processed, ensuring excellent dispersion and minimizing any negative impact on the polymer's mechanical properties or processing behavior.

Why Use Flame Retardant Masterbatch?

The advantages of using flame retardant masterbatches over neat flame retardant powders are numerous and significant:

- Improved Dispersion: Masterbatches ensure homogeneous distribution of flame retardants throughout the polymer matrix, leading to consistent fire performance and preventing localized "hot spots" of poor protection.

- Enhanced Processing Efficiency: They are easy to handle, flow well, and can be accurately dosed, leading to more efficient manufacturing processes and reduced production costs.

- Reduced Dust and Safety Hazards: Eliminating airborne powder reduces the risk of respiratory issues for workers and minimizes contamination in the production environment.

- Consistent Quality: Precise metering of masterbatch ensures consistent flame retardant levels in every batch, guaranteeing reliable product performance.

- Minimized Material Handling Losses: Less waste due to spillage or incomplete transfer compared to powders.

- Cleaner Operations: Reduced need for frequent cleaning of processing equipment.

Mechanisms of Flame Retardancy

Flame retardants function through various mechanisms to inhibit or delay ignition and flame spread. These mechanisms can be broadly categorized as:

- Physical Dilution: Inert gases released by some flame retardants (e.g., nitrogen, carbon dioxide from intumescent systems) dilute flammable gases in the flame zone, raising the minimum oxygen concentration required for combustion.

- Chemical Action in the Gas Phase: Some flame retardants release radicals (e.g., halogen-containing compounds) that interfere with the free radical chain reactions occurring in the gas phase during combustion, effectively "quenching" the flame.

- Chemical Action in the Condensed Phase:

- Char Formation: Certain flame retardants promote the formation of a stable, non-combustible char layer on the polymer surface. This char acts as a barrier, isolating the unburnt polymer from heat and oxygen, and inhibiting the escape of flammable volatile products. Intumescent systems are a prime example.

- Endothermic Decomposition: Some flame retardants decompose endothermically (absorbing heat) when exposed to fire, thereby cooling the polymer and delaying its decomposition. Aluminum hydroxide (ATH) and magnesium hydroxide (MDH) are common examples.

Types of Flame Retardant Additives Used in Masterbatches

Flame retardant masterbatches can incorporate a wide range of flame retardant chemistries, each with its own advantages and suitable applications:

-

Halogenated Flame Retardants (Brominated and Chlorinated):

- Mechanism: Primarily gas-phase radical scavengers.

- Examples: Decabromodiphenyl ethane (DBDPE), brominated epoxy oligomers, chlorinated paraffins.

- Pros: Highly efficient at low loading levels.

- Cons: Environmental concerns regarding potential for PBT (persistent, bioaccumulative, toxic) substances and generation of corrosive and toxic smoke during combustion. Regulatory pressures have led to a decline in their use in many applications.

-

Phosphorus-Based Flame Retardants:

- Mechanism: Primarily condensed-phase char formation. Some also exhibit gas-phase activity.

- Examples: Red phosphorus, ammonium polyphosphate (APP), organophosphates (e.g., triphenyl phosphate, resorcinol bis(diphenyl phosphate)).

- Pros: Often provide good charring capabilities, environmentally friendlier than halogenated alternatives.

- Cons: Some can be susceptible to hydrolysis, and certain types may have migration issues. Red phosphorus requires careful handling due to reactivity.

-

Inorganic Hydroxides (Mineral Flame Retardants):

- Mechanism: Endothermic decomposition and dilution in the condensed phase. They also release water vapor, diluting flammable gases.

- Examples: Aluminum Trihydroxide (ATH), Magnesium Dihydroxide (MDH).

- Pros: Non-halogenated, low smoke production, cost-effective.

- Cons: Require very high loading levels (often >50%) to be effective, which can negatively impact mechanical properties and processing.

-

Nitrogen-Based Flame Retardants (Melamine Derivatives):

- Mechanism: Gas-phase dilution (releasing nitrogen) and promotion of char formation in the condensed phase.

- Examples: Melamine cyanurate, melamine polyphosphate.

- Pros: Non-halogenated, good for certain polymers, synergize well with other flame retardants.

- Cons: Can have limited effectiveness on their own in some polymers.

-

Silicon-Based Flame Retardants:

- Mechanism: Promote the formation of a ceramic-like char layer on the polymer surface, acting as a barrier.

- Examples: Polysiloxanes.

- Pros: Good thermal stability, low smoke, non-halogenated.

- Cons: Can be more expensive, specific applications.

-

Intumescent Flame Retardant Systems:

- Mechanism: A combination of acid source, carbonific agent, and blowing agent. Upon heating, they form a thick, foamed, carbonaceous char layer that insulates the underlying polymer.

- Examples: Ammonium polyphosphate (acid source), pentaerythritol (carbonific agent), melamine (blowing agent).

- Pros: Highly effective, non-halogenated, low smoke and toxic gas production.

- Cons: Can be sensitive to moisture, may affect transparency, and require careful formulation.

Applications of Flame Retardant Masterbatches

Flame retardant masterbatches are indispensable in a vast array of applications where fire safety is paramount:

- Building and Construction: Cables and wires, pipes, insulation materials, roofing membranes, wall coverings, flooring.

- Electronics and Electrical: Casings for appliances, connectors, circuit board components, wire and cable jacketing, plugs.

- Automotive: Interior components (seats, dashboards, door panels), under-the-hood applications, cable insulation.

- Textiles: Upholstery, curtains, protective clothing, non-woven fabrics.

- Transportation: Aircraft interiors, train components, marine applications.

- Furniture: Foams, fabrics, structural components.

- Packaging: Specialized protective packaging.

Regulatory Landscape and Industry Trends

The regulatory environment for flame retardants is constantly evolving, driven by increasing awareness of environmental and health impacts. Key trends include:

- Shift Towards Non-Halogenated Solutions: Strict regulations (e.g., RoHS, WEEE, REACH) and growing consumer demand are pushing industries away from halogenated flame retardants towards more environmentally benign alternatives.

- Focus on Low Smoke and Toxicity: Beyond flame spread, the generation of smoke and toxic gases during a fire is a major concern for human safety. This has led to a greater emphasis on flame retardant systems that minimize these byproducts.

- Performance-Based Standards: Regulations are increasingly moving towards performance-based standards (e.g., UL 94, EN 45545 for railway applications, various building codes) rather than mandating specific chemistries, allowing for innovation in flame retardant formulations.

- Synergistic Systems: Formulators are increasingly developing synergistic combinations of different flame retardants to achieve desired fire performance at lower overall loading levels and optimize cost-effectiveness.

- Sustainable Solutions: Research and development are focused on bio-based flame retardants and more sustainable manufacturing processes for these additives.

Challenges and Future Outlook

Despite the significant advancements, challenges remain in the flame retardant masterbatch industry:

- Balancing Performance and Properties: Achieving high flame retardancy without compromising the mechanical properties, aesthetics, or processability of the polymer remains a continuous challenge.

- Cost-Effectiveness: Developing effective non-halogenated solutions that are economically viable for mass production.

- Migration and Leaching: Ensuring the long-term stability of flame retardants within the polymer matrix and preventing their migration or leaching, especially in sensitive applications.

- Recyclability: Designing flame retardant systems that do not hinder the recyclability of polymeric materials.

The future of flame retardant masterbatches will be characterized by continued innovation in non-halogenated chemistries, enhanced synergistic formulations, and a stronger emphasis on sustainable and circular economy principles. As industries strive for safer products and a more sustainable future, flame retardant masterbatches will undoubtedly remain a cornerstone in ensuring fire safety across the vast landscape of polymeric materials.