Enhancing Polyamide Performance: The Role of Functional Additives

2025-12-09

The Versatile World of Polyamides (PA)

Polyamides (PA), commonly known as nylons, are a family of synthetic polymers that have fundamentally shaped modern engineering and manufacturing. From the tough, abrasion-resistant fibers in clothing and carpets to the robust components in automotive engines and electronics, PAs are valued for their excellent balance of properties. They offer high strength, good chemical resistance, impressive thermal stability, and low friction.

However, the base properties of pure polyamide often fall short of the demanding specifications required for specialized applications. This is where Functional Additives For PA become essential. These additives are chemical compounds mixed into the polymer during processing to intentionally modify and enhance the final material’s characteristics, tailoring it for specific real-world challenges.

Key Categories of Functional Additives

Functional additives transform standard PA into high-performance engineering plastics. These additives can be broadly categorized based on the primary function they serve:

1. Thermal and Oxidative Stabilizers

Polyamides, like many plastics, can degrade when exposed to high temperatures, especially in the presence of oxygen—a process known as thermal oxidation. This degradation leads to a loss of mechanical strength, discoloration, and a reduction in service life.

- Antioxidants: These are crucial for applications like under-the-hood automotive parts or electrical connectors that experience continuous high heat. Phenolic and phosphite compounds are commonly used. They work by scavenging free radicals, which are the highly reactive molecules responsible for initiating the degradation chain reaction. This “radical trapping” mechanism significantly extends the PA’s useful life and maintains its mechanical integrity at elevated temperatures.

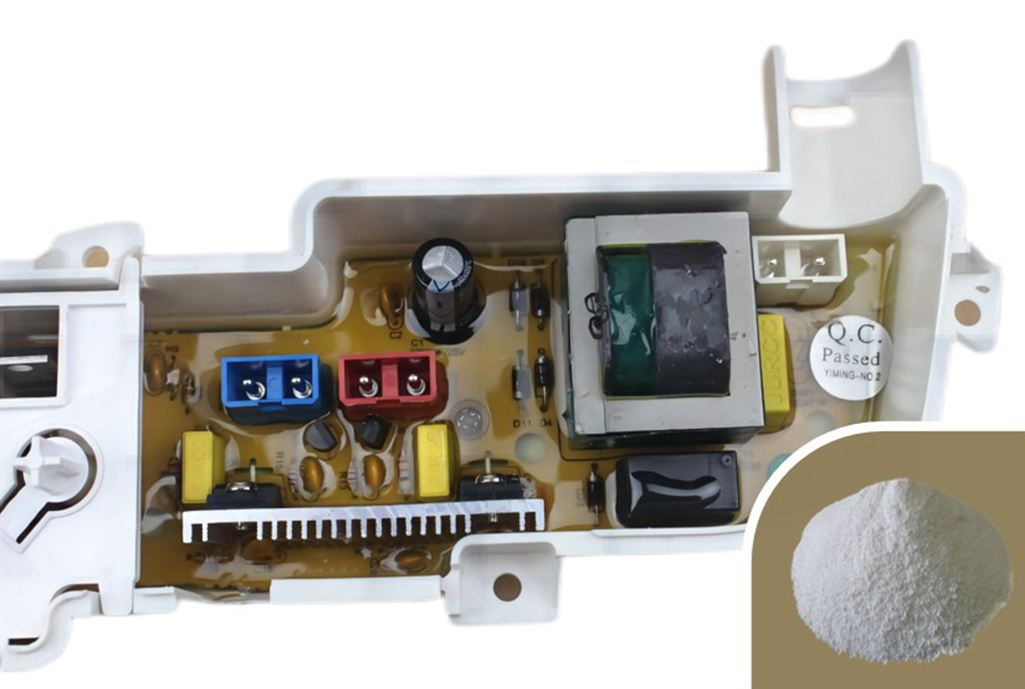

2. Flame Retardants

In applications where fire safety is paramount—such as electronics, construction materials, and transportation—polyamides must resist ignition and self-extinguish when a flame source is removed.

- Halogenated and Halogen-Free Systems: Traditionally, halogen-containing additives (like bromine compounds) were effective but have faced environmental scrutiny. The trend is moving towards high-performance, halogen-free flame retardants (HFFR), such as red phosphorus, melamine derivatives, and metal phosphinates. These often work in the solid phase by forming a protective char layer that insulates the underlying polymer from the heat and oxygen, or in the gas phase by releasing non-flammable gases that dilute the fuel source.

3. Impact Modifiers

While polyamides are inherently tough, they can become brittle at lower temperatures, limiting their use in cold environments or in parts that require exceptional resistance to sudden shocks (high impact strength).

- Elastomers: Adding a finely dispersed rubbery phase, typically various forms of functionalized polyolefins or styrene-based block copolymers, dramatically improves impact resistance. These soft, rubber particles act as “stress concentrators” when the material is subjected to impact. Instead of a crack propagating through the rigid PA matrix, the energy of the impact is absorbed by the elastic deformation of the rubber particles, preventing catastrophic failure.

4. Colorants and UV Stabilizers

For outdoor applications, PAs need protection from sunlight, which can cause chalking, fading, and degradation over time.

- UV Absorbers and Hindered Amine Light Stabilizers (HALS): UV absorbers shield the polymer by absorbing the harmful ultraviolet radiation and dissipating it as harmless heat. HALS compounds, on the other hand, actively interrupt the photo-oxidative degradation process caused by UV light, offering long-term protection against weathering.

- Pigments and Dyes: Color is an additive that serves both aesthetic and functional purposes (e.g., identifying components). Inorganic pigments (like titanium dioxide for white) and specialized organic dyes are added to achieve the desired hue while maintaining thermal stability.

Processing Enhancements

Beyond modifying the final material properties, some Functional Additives For PA are designed to improve the manufacturing process itself.

1. Nucleating Agents

Polyamides are semi-crystalline polymers, meaning they contain both amorphous (disordered) and crystalline (ordered) regions. The size and density of the crystalline structure significantly influence the material’s mechanical properties, shrinkage, and warpage.

- Function: Nucleating agents (such as talc or specific metal salts) introduce tiny, uniform sites throughout the molten polymer. When the PA cools, crystallization begins simultaneously at these numerous sites. This results in smaller, more uniform crystals (crystallites), which speeds up the solidification process, reduces cycle time in injection molding, and helps minimize part shrinkage and distortion.

2. Lubricants and Mold Release Agents

These additives improve the flow of the molten plastic during molding and ensure easy removal of the finished part from the mold cavity. They reduce friction, lower processing temperatures, and minimize wear and tear on expensive molds, leading to greater efficiency and lower production costs.

The Future of PA Additives

The field of Functional Additives For PA is constantly evolving, driven by the demand for lighter, stronger, and more sustainable materials. The current focus is heavily on:

- Non-Halogenated Systems: Developing highly effective, environmentally friendly flame retardants.

- Bio-based Additives: Incorporating additives derived from renewable resources to reduce the polymer’s carbon footprint.

- Multi-functional Additives: Creating single compounds that simultaneously offer protection against heat, UV light, and oxidation, simplifying the compounding process.

By precisely tuning the chemical composition with functional additives, manufacturers can unlock the full potential of polyamides, ensuring they remain one of the most vital and versatile materials in the world of engineering plastics.