The Definitive Guide to Flame Retardant Masterbatch for PA

2026-02-03

Understanding Flame Retardant Masterbatch for Polyamide (PA)

Polyamide, commonly known as Nylon (PA6 or PA66), is a cornerstone material in engineering due to its exceptional mechanical strength and thermal stability. However, its inherent flammability poses significant risks in high-stakes environments like automotive engines and electrical housings. Using a Flame Retardant Masterbatch for PA is the most efficient way to mitigate these risks. Unlike powder additives, masterbatches are concentrated mixtures of flame-retardant agents encapsulated in a carrier resin. This format ensures superior dispersion throughout the polymer matrix, preventing "hot spots" where the material might remain vulnerable to ignition. By integrating these concentrates, manufacturers can achieve stringent safety ratings, such as UL94 V-0, without compromising the structural integrity of the nylon component.

Key Advantages of Using Masterbatch Over Powder Additives

Choosing a PA flame retardant concentrate offers several logistical and technical benefits over traditional raw powder mixing. The primary advantage is the elimination of dust hazards, which improves factory hygiene and worker safety. Furthermore, masterbatches are engineered to be pelletized, making them compatible with standard injection molding and extrusion dosing systems. This leads to higher dosing accuracy and consistent batch-to-batch quality.

- Enhanced Dispersion: Pre-dispersed pigments and retardants prevent clumping during processing.

- Reduced Screw Wear: The carrier resin acts as a lubricant, reducing the abrasive impact on machinery compared to raw chemical powders.

- Moisture Control: Many PA-specific masterbatches are formulated to handle the hygroscopic nature of nylon, reducing the risk of hydrolysis during high-temperature molding.

Comparison of Halogenated vs. Halogen-Free Flame Retardants (HFFR)

When selecting a nylon flame retardant masterbatch, the choice often comes down to environmental regulations and the specific application. Halogenated versions (typically bromine-based) are highly effective and cost-efficient but are increasingly being replaced by Halogen-Free Flame Retardant (HFFR) solutions due to toxicity concerns during combustion. Below is a comparison of their performance characteristics in Polyamide applications:

| Feature | Brominated Masterbatch | Halogen-Free (Red Phosphorus/Nitrogen) |

| Fire Rating | UL94 V-0 (Excellent) | UL94 V-0 to V-2 (Good) |

| Smoke Density | High | Low |

| Mechanical Retention | Moderate | High |

| Environmental Compliance | Strict (RoHS/REACH) | Environmentally Friendly |

Critical Application Areas for Fire Retardant Nylon Compounds

The demand for PA6 and PA66 flame retardant masterbatch is driven by sectors where electrical conductivity and heat generation are constants. Because Polyamide is often reinforced with glass fiber (GF), the masterbatch must be potent enough to counteract the "candle-wick effect," where the glass fibers can actually facilitate the spread of flames.

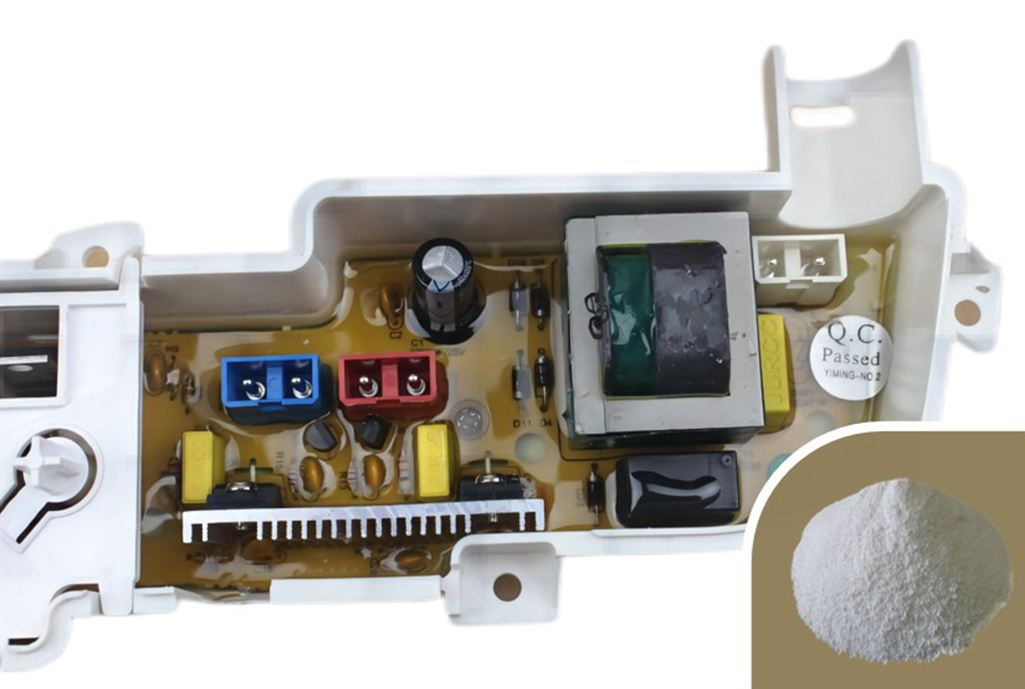

Electrical and Electronics (E&E)

Connectors, circuit breakers, and switchgear components require the highest safety standards. Using a masterbatch ensures that even complex, thin-walled geometries maintain a consistent level of fire protection, preventing catastrophic failures in consumer electronics and industrial power grids.

Automotive Engineering

As the automotive industry shifts toward electric vehicles (EVs), the need for fire-safe battery housings and high-voltage cable insulation has skyrocketed. Specialized flame retardant additives for PA allow these components to withstand extreme thermal runaway events, providing critical time for passenger evacuation and system shutdown.

Best Practices for Processing and Dosage

To achieve the best results with a fire resistant masterbatch for nylon, processors must pay close attention to temperature profiles. Polyamide has a high melting point, and if the processing temperature exceeds the decomposition temperature of the flame retardant agent, the material may "outgas," leading to surface defects or reduced mechanical properties. It is generally recommended to keep processing temperatures below 280°C for most HFFR nylon systems. Additionally, ensure the base resin is thoroughly dried to a moisture content below 0.1% to prevent the masterbatch from reacting negatively with water vapor during extrusion.