Navigating the Shift to Halogen-Free: Optimizing Flame Retardant Masterbatch for Polypropylene Applications

2026-01-27

The Evolution of Fire Safety in Polypropylene

Polypropylene (PP) has cemented its status as a dominant material in automotive, construction, and electronics due to its chemical resistance and mechanical versatility. However, its high aliphatic hydrocarbon content makes it inherently flammable, with a limiting oxygen index (LOI) of approximately 17-18%, well below the atmospheric oxygen concentration. This necessitates the use of high-performance flame retardant (FR) masterbatches to meet stringent safety standards like UL94 V-0.

The current industry landscape is witnessing a decisive pivot from traditional brominated systems toward advanced halogen-free flame retardant (HFFR) masterbatches. This shift is driven not only by regulatory frameworks such as REACH and RoHS but also by the need for lower smoke density and reduced corrosivity during processing. Modern masterbatches are no longer just about suppressing fire; they are engineered additives that must maintain the polymer's mechanical integrity, UV stability, and processability.

Comparative Analysis: Halogenated vs. Halogen-Free Systems

Selecting the correct masterbatch requires balancing efficiency, cost, and environmental impact. While halogenated systems offer high efficiency at low loadings, halogen-free alternatives are essential for eco-conscious applications and enclosed spaces where smoke toxicity is a concern.

| Feature | Halogenated (Bromine/Antimony) | Halogen-Free (Intumescent/P-N) |

| Mechanism | Gas-phase radical scavenging | Condensed-phase char formation |

| Loading Level | Low (2-10%) | Moderate to High (20-30%+) |

| Smoke Density | High | Low |

| Density of Final Part | Higher (heavy metal synergists) | Lower (lightweight advantage) |

| UV Stability | Moderate (prone to yellowing) | Good (with specific stabilizers) |

Mechanisms of Action: Radical Scavenging vs. Intumescence

Radical Scavenging (Halogenated)

Traditional masterbatches containing decabromodiphenyl ethane (DBDPE) or tetrabromobisphenol A (TBBPA) operate in the gas phase. When the PP ignites, the halogen radicals (Br•) are released. These radicals react with the highly reactive hydrogen and hydroxyl radicals (H• and OH•) that propagate the combustion chain, effectively "poisoning" the flame and halting the exothermic reaction. Antimony trioxide ($Sb_2O_3$) is almost always added as a synergist to facilitate the release of halogen radicals at the correct temperature.

Intumescent Char Formation (Halogen-Free)

Phosphorus-nitrogen (P-N) based masterbatches work primarily in the condensed phase. Upon heating, the acid source (like ammonium polyphosphate) dehydrates the carbon source (often the polymer itself or a synergist like pentaerythritol), creating a cross-linked carbonaceous char. Simultaneously, a blowing agent (like melamine) releases non-flammable gases that swell this char into a thick, insulating foam layer. This layer acts as a physical barrier, blocking heat transfer to the underlying polymer and preventing oxygen from reaching the fuel source.

Critical Processing Guidelines for Masterbatch Dispersion

The effectiveness of a flame retardant masterbatch for PP is directly tied to how well it is dispersed within the PP matrix during extrusion or injection molding. Poor dispersion leads to "hot spots" where flammability remains high, causing test failures despite correct loading levels.

- Temperature Control: Many halogen-free intumescent additives have a decomposition onset around 250°C. Processing temperatures should be kept strictly below this limit to prevent premature activation of the foaming mechanism inside the barrel, which causes splay marks and loss of FR efficiency.

- Screw Design: Use a screw with moderate shear. While mixing is essential, excessive shear heat can degrade the flame retardant additives. A barrier screw or a dedicated mixing section (like Maddock) is recommended to ensure homogeneity without overheating the melt.

- Moisture Management: P-N based masterbatches are often hygroscopic. If the masterbatch is not pre-dried (typically 2-4 hours at 80°C), moisture turns to steam during processing. This results in hydrolytic degradation of the polymer and surface defects such as silver streaking.

Troubleshooting Common Extrusion Defects

When integrating high loadings of flame retardant masterbatch, processors often encounter specific defects. Addressing these requires a systematic approach to formulation and machine settings.

Die Buildup (Plate-out)

This occurs when low-molecular-weight components of the flame retardant migrate to the die exit, accumulating and eventually dragging on the product surface. To mitigate this, check for compatibility issues between the carrier resin of the masterbatch and the base PP. Additionally, slightly reducing the die temperature can increase melt strength and reduce migration.

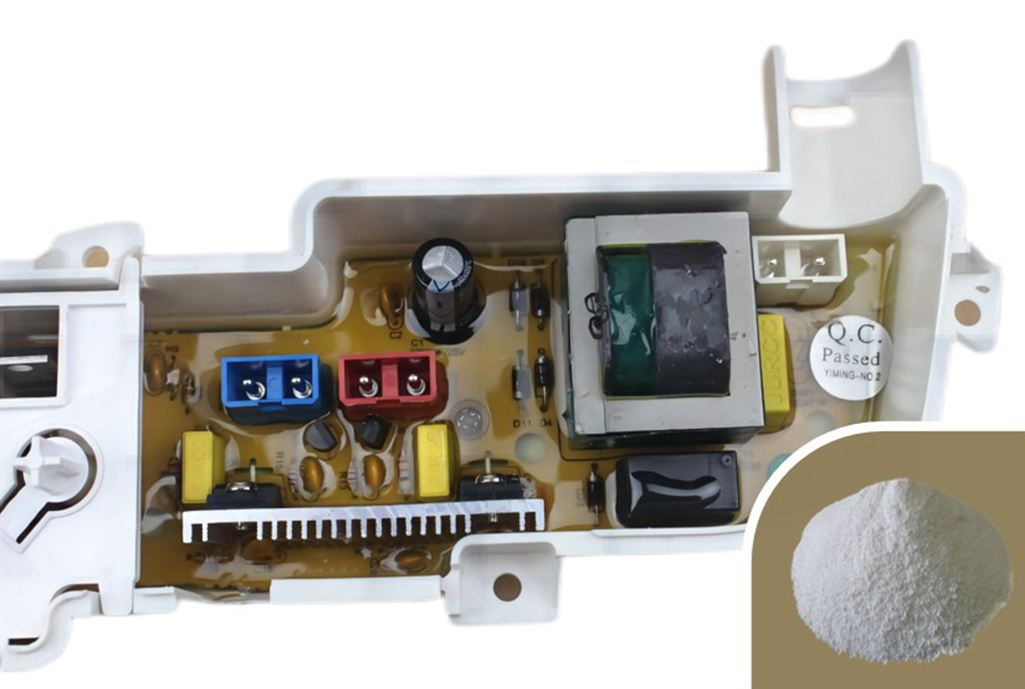

Blooming

Blooming appears as a white, powdery residue on the surface of the finished part days or weeks after production. This is often caused by the migration of the flame retardant to the surface due to incompatibility or excessive loading. Switching to a masterbatch with a polymerized, high-molecular-weight flame retardant that is anchored to the PP matrix is the most effective permanent solution.

Impact Strength Reduction

Flame retardants act as contaminants in the crystal lattice of polypropylene, often making the material brittle. If impact resistance is critical, the masterbatch formulation should include a compatibilizer (like maleic anhydride grafted PP) or an impact modifier (like elastomers) to regain toughness without compromising the UL94 rating.