Functional Additives Masterbatch: Revolutionizing Polymer Performance

2025-10-01

In the world of polymer processing, achieving a desired end-product often requires more than just the base resin. Enhancing properties like durability, flame resistance, UV stability, or anti-static capabilities is crucial for a wide range of applications. This is where Functional Additives Masterbatch comes in, a game-changing solution that streamlines the compounding process and unlocks new levels of performance for plastic materials.

What is a Masterbatch?

At its core, a masterbatch is a concentrated mixture of pigments or additives encapsulated in a carrier resin. Instead of adding raw, powdered additives directly to a polymer during processing, a masterbatch provides a clean, dust-free, and easy-to-handle solution. This method ensures excellent dispersion of the additives throughout the final product, preventing clumping and inconsistencies that can compromise performance.

The Power of Functional Additives Masterbatch

While color masterbatches are widely known, functional additives masterbatch focuses on imparting specific technical properties to the polymer. It’s a specialized product designed to solve complex performance challenges. This concentration of active ingredients allows manufacturers to precisely dose and introduce high-performance additives with minimal effort and maximum efficiency.

Here are some key types of functional additives commonly delivered via masterbatch:

-

UV Stabilizers: These additives protect polymers from degradation caused by prolonged exposure to sunlight. They are essential for outdoor applications like garden furniture, automotive parts, and agricultural films, preventing discoloration, embrittlement, and loss of mechanical strength.

-

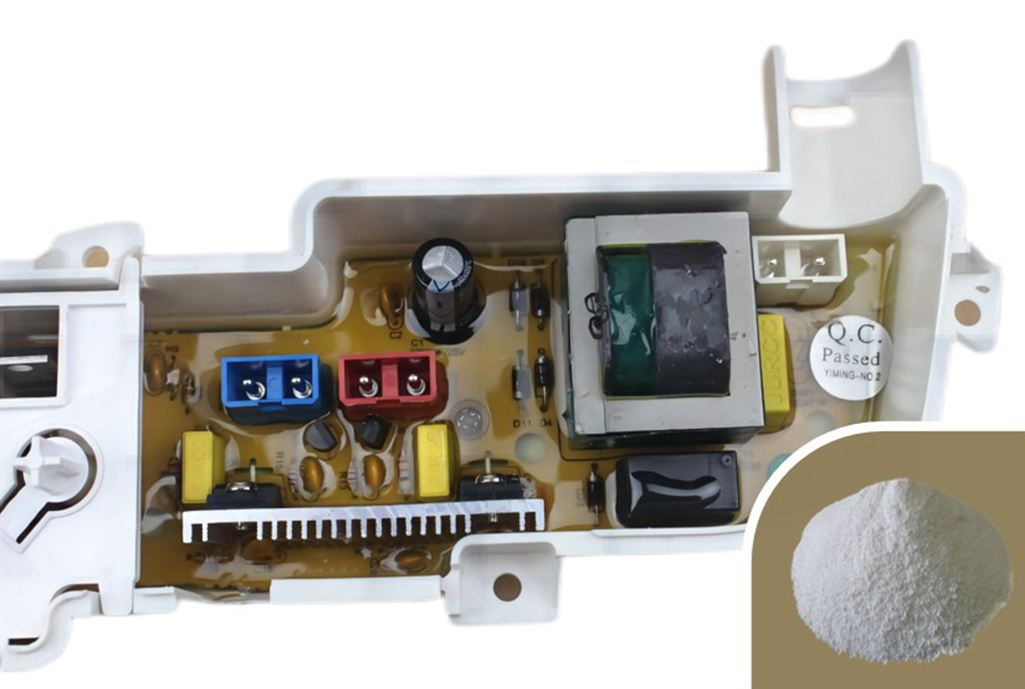

Flame Retardants: Critical for applications in electronics, construction, and transportation, flame retardant masterbatches help polymers resist ignition and slow the spread of fire. They are vital for meeting stringent safety and regulatory standards.

-

Antioxidants: These compounds prevent polymer degradation during high-temperature processing and throughout the product's lifespan. By inhibiting oxidation, antioxidants extend the service life of plastics and maintain their physical properties over time.

-

Anti-static Agents: Static electricity can be a significant problem in packaging, electronics, and textiles. Anti-static masterbatches reduce surface resistivity, preventing static charge buildup and the attraction of dust.

-

Slip and Anti-block Agents: Used primarily in film applications, slip agents reduce the coefficient of friction, allowing film layers to slide past each other easily. Anti-block agents prevent film layers from sticking together, ensuring smooth processing and handling.

-

Optical Brighteners: These additives absorb UV light and re-emit it in the visible blue spectrum, making polymers appear whiter and brighter. They are commonly used in packaging, consumer goods, and textiles.

Advantages of Using Masterbatch

Choosing a functional additives masterbatch over direct powder dosing offers several significant benefits:

-

Improved Dispersion: The additives are pre-dispersed in a compatible carrier resin, ensuring uniform distribution and consistent performance throughout the final product.

-

Enhanced Processing Efficiency: Masterbatches are free-flowing pellets that are easy to handle and measure, eliminating the dust, mess, and potential health hazards associated with powdered additives. This also allows for more precise and automated dosing.

-

Cost-Effectiveness: While the upfront cost of a masterbatch can be higher than raw additives, the long-term benefits of reduced waste, consistent quality, and enhanced production efficiency often lead to overall cost savings.

-

Safety and Cleanliness: The pelleted form reduces the risk of airborne powders, improving workplace safety and cleanliness.

The Future of Polymer Innovation

The demand for specialized, high-performance plastics continues to grow across all industries. From advanced medical devices to lightweight automotive components, the need for tailored material properties is more critical than ever. Functional additives masterbatch stands at the forefront of this innovation, providing a flexible and efficient way for manufacturers to meet these complex demands. As technology evolves, we can expect to see even more sophisticated masterbatch solutions that enable the creation of smarter, more sustainable, and higher-performing polymer products.