Enhancing Polyamides: The Role of Flame Retardant Masterbatch for PA

2025-10-22

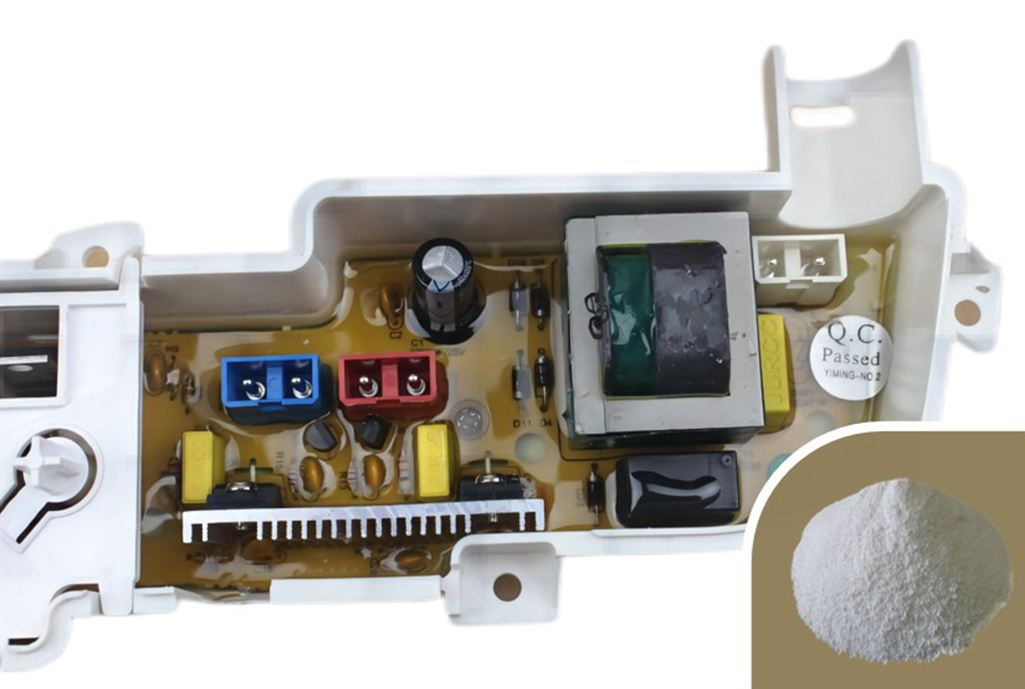

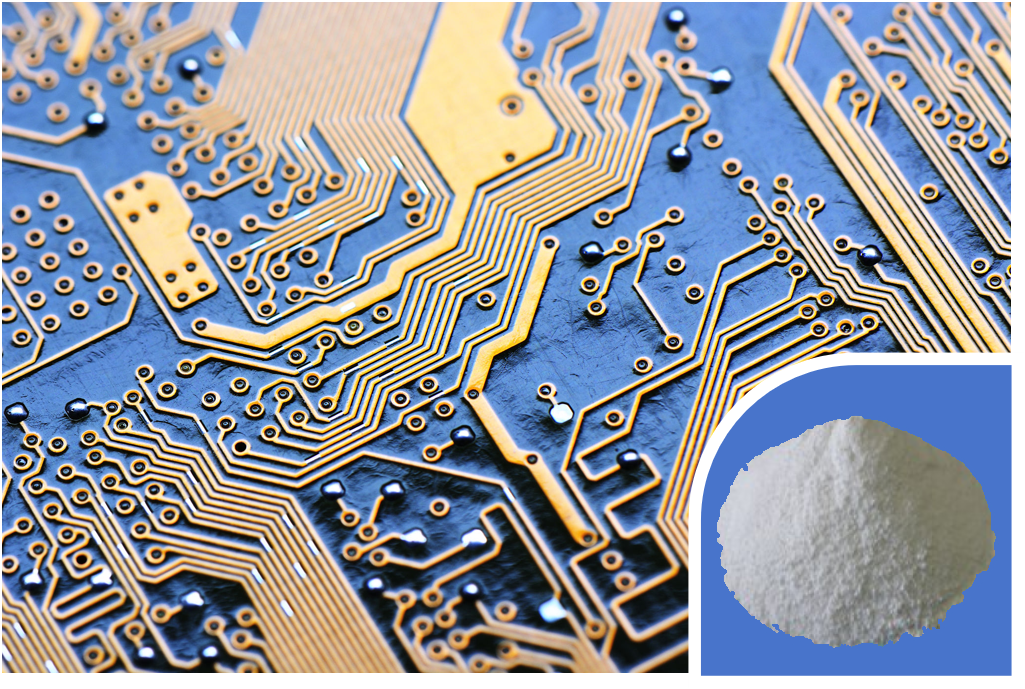

Polyamides, commonly known as nylons (PA), are versatile engineering plastics celebrated for their excellent mechanical strength, toughness, and resistance to heat and chemicals. They find widespread use in demanding applications across the automotive, electrical and electronics (E&E), and construction industries. However, like most organic polymers, standard polyamides are flammable, which presents a significant hazard in applications where fire safety is paramount.

To meet stringent fire safety standards and regulatory requirements, manufacturers must modify PA materials to improve their resistance to ignition and flame spread. This is where the specialized product, Flame Retardant Masterbatch for PA, becomes essential.

What is Flame Retardant Masterbatch for PA?

A masterbatch is a concentrated mixture of additives, often in the form of granules, that is incorporated into a base polymer during the manufacturing process. The Flame Retardant Masterbatch for PA specifically contains high concentrations of flame-retardant (FR) chemicals dispersed within a carrier resin that is compatible with polyamide.

This method offers several significant advantages over directly compounding the raw FR powder into the polymer:

-

Ease of Processing: Masterbatches are typically solid granules that flow easily and mix uniformly with the raw PA resin, ensuring consistent dispersion and dosing.

-

Cleaner Handling: FR powders can be dusty, posing health and safety risks, and leading to process contamination. The masterbatch format eliminates this issue.

-

Improved Dispersion: The FR additives are pre-dispersed and encapsulated within the carrier, which helps achieve optimal and consistent distribution throughout the final PA product.

Key Components and Mechanisms

The effectiveness of a Flame Retardant Masterbatch for PA lies in its active ingredients and the mechanism by which they interfere with the combustion cycle. The FR systems typically employed for polyamides include:

1. Halogenated Systems (Less Common Due to Environmental Concerns)

While effective, these systems release dense smoke and corrosive, toxic gases (like hydrogen halides) during a fire, leading to their gradual phasing out in many applications, especially in the E&E sector.

2. Halogen-Free Systems (HFFR)

These are increasingly preferred due to their environmental benefits and lower smoke production. They typically rely on one of the following chemistries:

-

Phosphorus-based FRs (e.g., Red Phosphorus, Phosphate Esters): These primarily work in the condensed phase. Upon heating, they form a non-volatile, carbonaceous protective layer, or char, on the surface of the burning material. This char acts as a barrier, preventing the transfer of heat to the underlying polymer and blocking the escape of flammable gases.

-

Nitrogen/Phosphorus Synergistic Systems: Often utilizing compounds like Melamine Polyphosphate (MPP), these systems exhibit synergistic effects. The nitrogen-containing components act as blowing agents that expand the char layer, further insulating the material and diluting the flammable gases in the gas phase.

The selection of the specific FR system within the Flame Retardant Masterbatch for PA is crucial and depends on the PA type (PA6, PA66, etc.) and the required flammability standard, such as the widely recognized UL 94 rating (e.g., V-0, V-2).

Applications and Benefits

The use of Flame Retardant Masterbatch for PA is critical for material compliance and safety in high-risk environments.

Target Applications:

Key Benefits of the Product:

-

Achieving Compliance: It allows PA materials to reliably meet international fire safety standards (like UL 94 V-0, IEC, and ASTM).

-

Preserving Mechanical Properties: Formulations are optimized to minimize the negative impact of the FR additives on PA's inherent strength, impact resistance, and processability.

-

Cost-Effective Dosing: Being a concentrate, a smaller amount of the Flame Retardant Masterbatch for PA is needed compared to the final product's weight, making dosing efficient and cost-effective.

In conclusion, the Flame Retardant Masterbatch for PA is an indispensable tool for engineers and manufacturers, enabling the safe and compliant deployment of high-performance polyamide plastics in safety-critical applications worldwide.